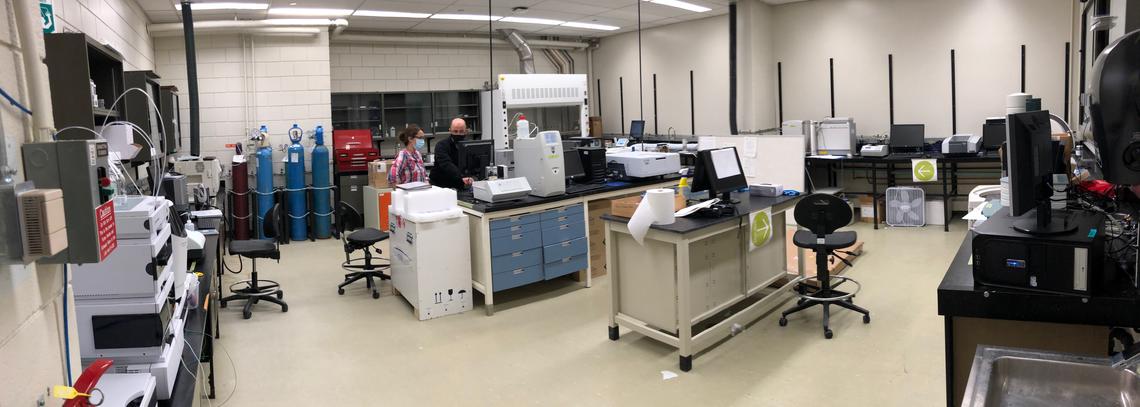

Research Instrumentation and Technical Support Lab

Department of Chemical and Petroleum Engineering

About the lab

The Department of Chemical and Petroleum Engineering has established a suite of instruments for chemical analysis and materials characterization to support research activities. These instruments are housed in the Research Instrumentation and Technical Support (RITS) Lab, are available for use by all researchers, and are supported by a dedicated research technician.

The lab specializes in sample analysis of:

- Structure

- Composition

- Morphology

- Contaminants and trace elements

- Particle size distribution

- Surface charge

- Thermal stability

- Catalyst load

- Analyte concentration

- UV-Vis absorption spectrum

3 ways to access the RITS Lab

Available instruments

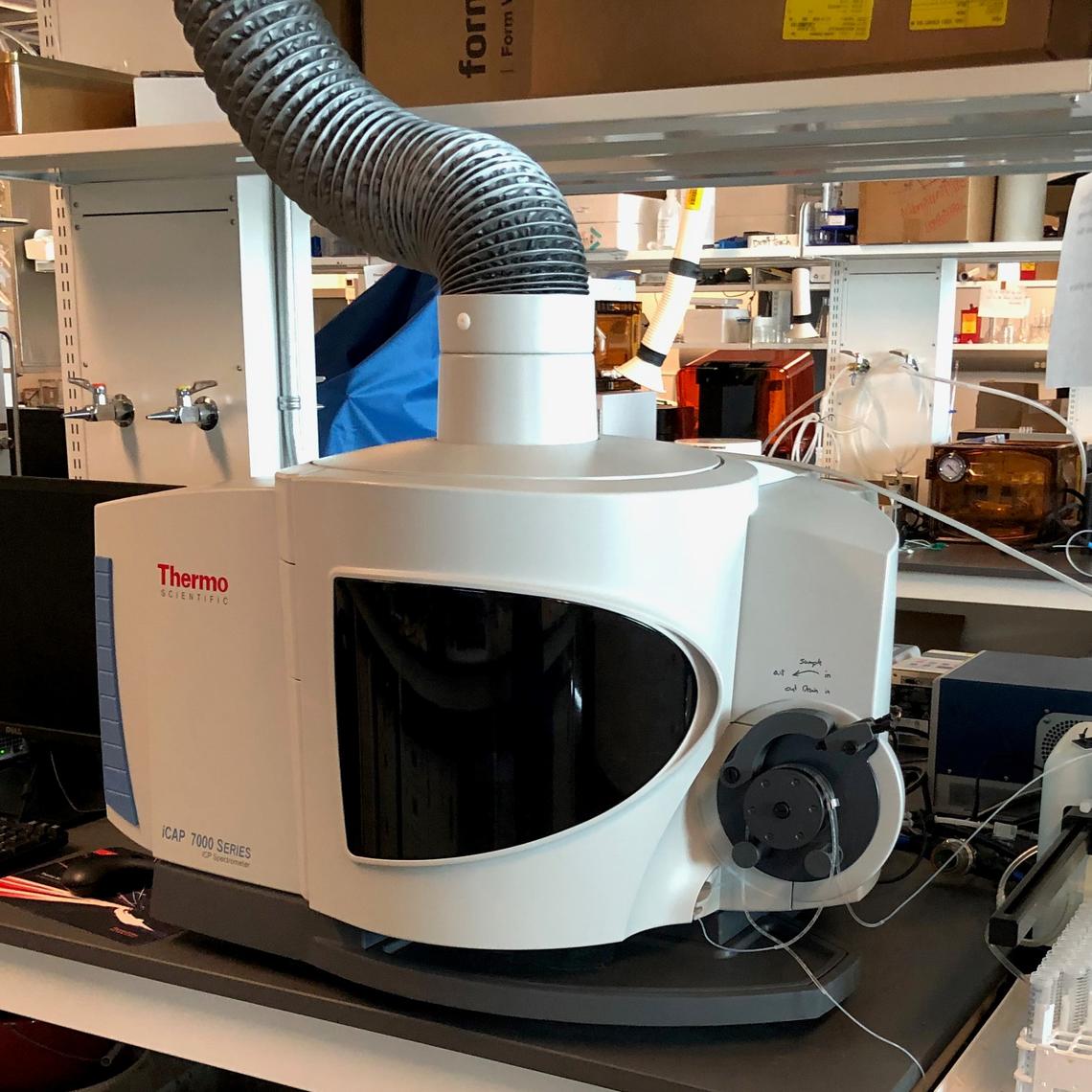

ICP-OES can be used to detect chemical elements, usually dissolved in water. It uses a plasma to excite the atoms/ions and determines the elements present based on the spectrum of their electromagnetic radiation at characteristic wavelengths. The sample is injected into a flame (the plasma) which is at a temperatures from 6,000 to 10,000 K. The intensity of this emission is related to the concentration of the element within the sample. The technique is very sensitive, so it can be used to detect contaminants and trace elements in environmental samples. Solid samples can be digested in acid followed by ICP-OES of the resulting aqueous samples to determine the amount of each element present in the original sample. It can be used for many different applications including:

- Water treatment: concentrations of inorganic elements (e.g. heavy metals, Mg, Ca, Si etc.)

- Loading and composition of catalysts samples

- Inorganic content of residues such as fly ash

- Inorganic content of oils

Model: iCAP 7200 Thermo Scientific iCAP 7000 series

Detection limit about 2 ppb (ug/L), Radial, Wavelength Range: 166-847 nm, Autosampler

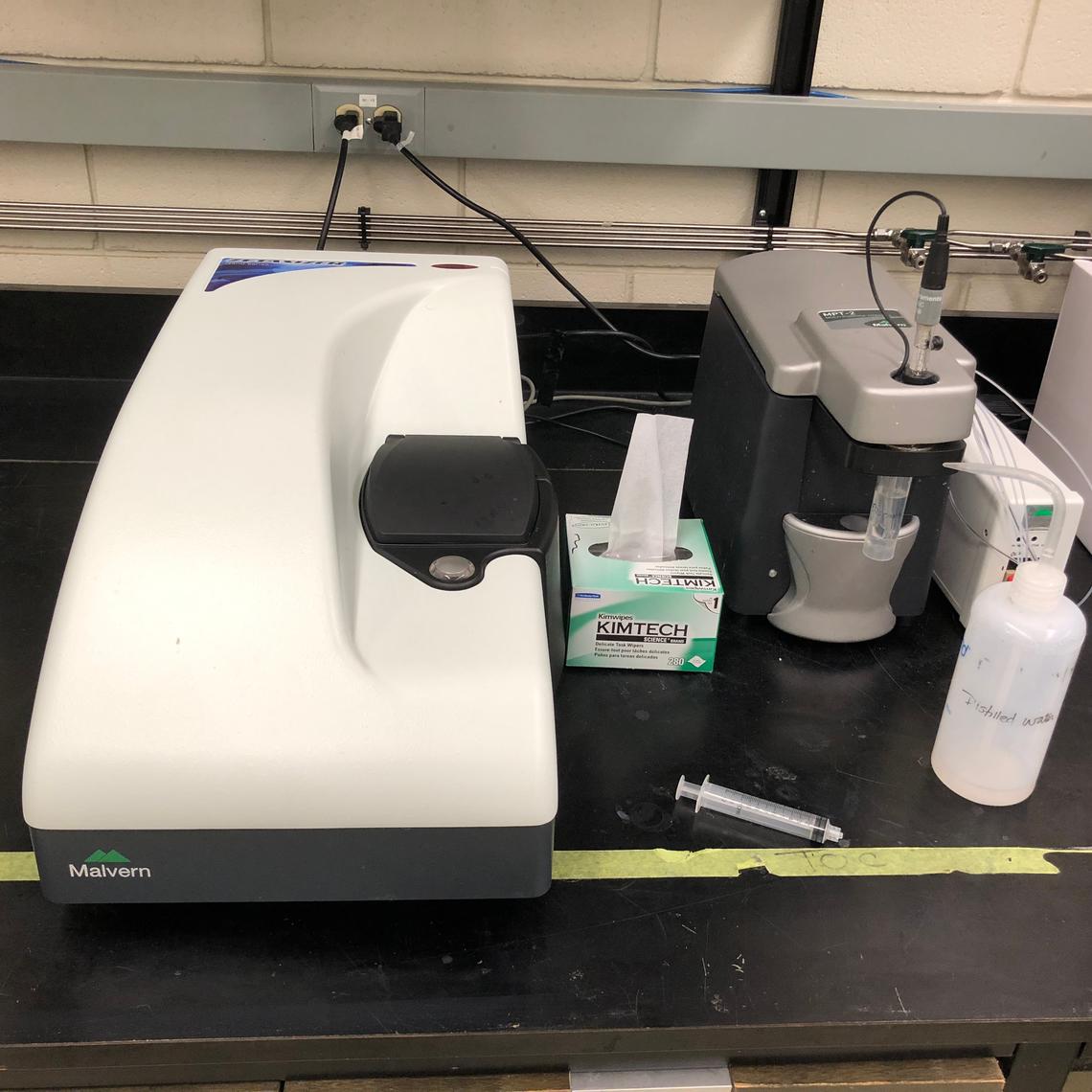

Studies the variation of intensity of scattered light from small particles, which can be used to determine the particle size distribution (PSD) due to differences in the Brownian motion. Using this technique it is also possible to determine the surface charge by imposing a potential gradient and observing the electrophoretic motion of the particles. The surface charge measured is the potential at the hydrodynamic slip plane, called the zeta potential. The surface charge affects electrostatic interactions, and is important in many processes. The effect of pH on the zeta potential can be studied using this technique, to determine the point of zero charge (PZC). This can be important when trying to understand the stability of colloidal systems as well as electrostatic interactions with charged and polar species. The technique can be used for many different applications, including:

- Characterization of polymers, surfactants, colloids and nanoparticles

- Characterization of cells and biological molecules such as proteins

- Stability of colloids and emulsions, by observing changes in the PSD

- Characterization of Surface charge of adsorbents and filters, which affects their interactions with charged and polar species

- Optimizing flocculants dose in water treatment

- Effect of functionalization of surfaces and suspended particles on surface charge

Model: Malvern Zetasizer Nano ZS

Particle size: 0.3 nm up to 10 mm (diameter)

Zeta potential measurement at a range of pH using an Autotitrator, suspension system, sample concentration: 0.1 ppm-40% w/v, temperature control: 0-90 0C, surface zeta potential measurement

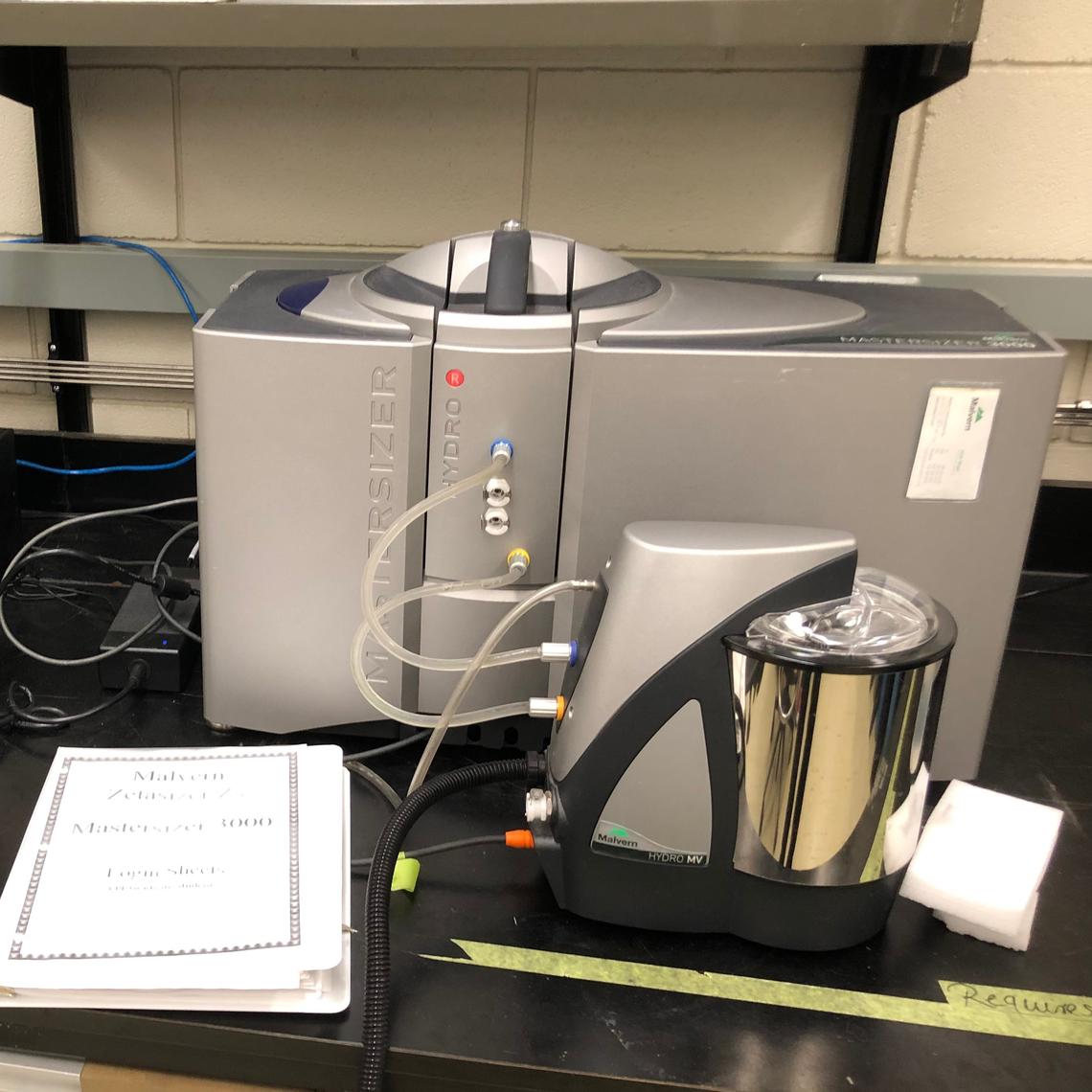

Can determine particle size distribution (PSD) of suspended samples from the diffraction patterns produced by a laser beam passing through the sample. Particle sizes from the 10s of nm to millimeter diameters can be determined using this technique. In the systems available samples must be dispersed in liquid, usually water. The technique can be used for particle size characterization of a wide range of systems, provided they can be dispersed in water (or a suitable liquid). Example applications include:

- Sediments, sand, clay, soil, tailings

- Powders (e.g. polymers, cement, ceramics)

- Precipitates

- Emulsions

- Inks

Model: Two instruments are available

Beckman Coulter LS 13320 and Malvern Mastersizer 3000

Both have a liquid dispersion module, for analysis of samples suspended in aqueous solution. Size range (0.04 um-2mm).

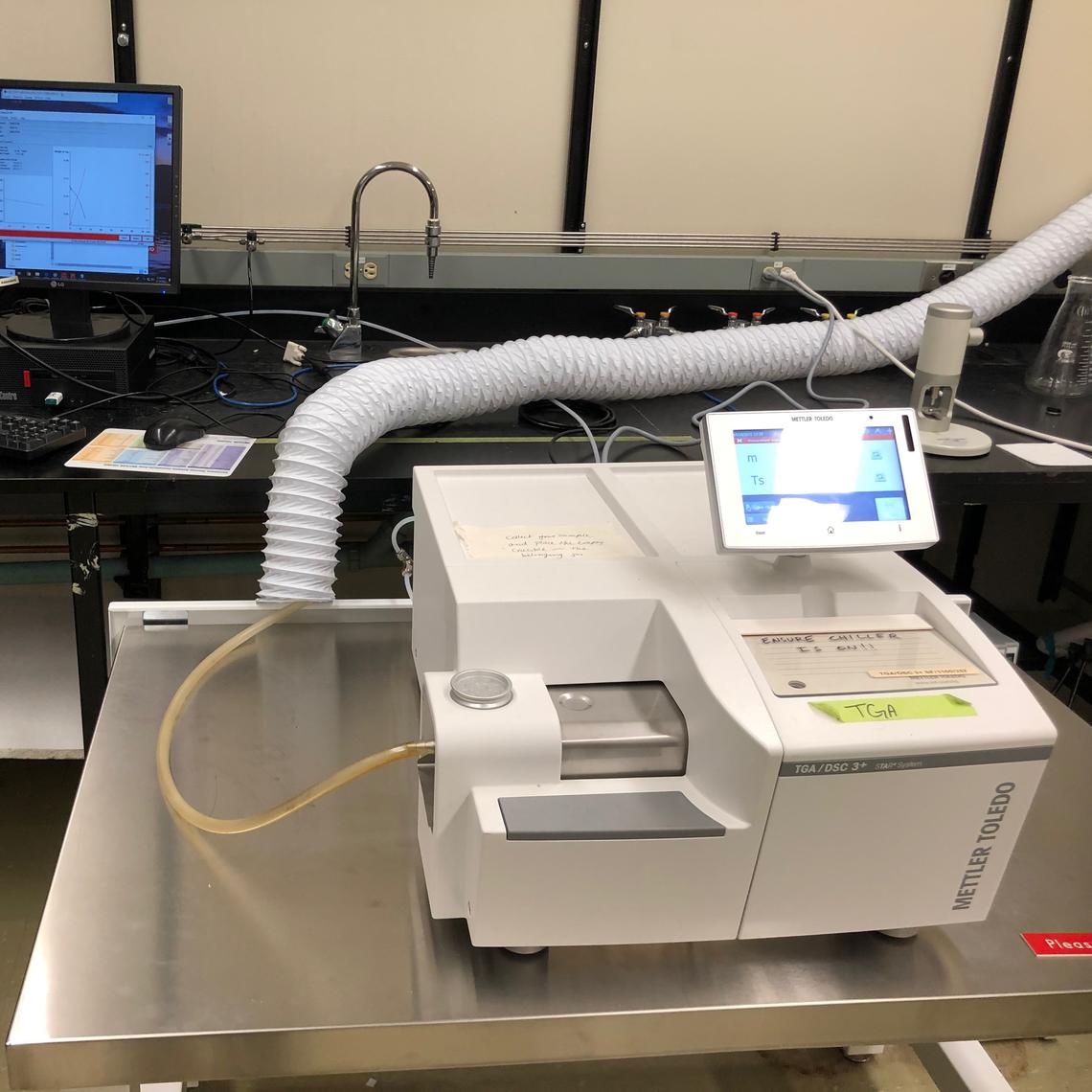

TGA is a method where changes in the mass of a sample are measured over time as the temperature changes. The measurements can be carried out in different environments (e.g. in air or nitrogen) and can provide information about phase transitions, absorption / adsorption, chemisorption, thermal decomposition and solid gas reactions. Applications include:

- Thermal stability of materials (e.g. polymers, carbons, catalysts, ceramics)

- Oxidation / combustion of materials (e.g. polymers, carbons, metals, alloys)

- Catalyst loadings can be determined by oxidation / gasification of the support material

Model: Mettler Toledo TGA/DSC3+

Min sample weight: 2 mg- Alumina crucible. Max temperature: 1100 ºC. Operation under air, carbon dioxide, or nitrogen. Heating rate: 0.020 to 250 ºC/min.

SEM is an electron microscope in which the surface of a specimen is scanned via high energy electrons that are reflected to generate a variety of signals to form a 2-D image. This provides the user with information about sample’s crystalline structure, chemical composition, morphology (texture), and orientation of materials making up the sample. The SEM is capable of performing a qualitative spot (Point) analysis which is useful in chemical composition measurement using the energy-dispersive X-ray spectroscopy (EDS). This technique determines the elements present in the sample based on the energy spectrum of emitted X-rays when the sample is excited by the electrons in the SEM. Applications include:

- Biological Samples

- Soil and rock sampling

- Material science

Model: Phenom Pro X

Electron voltage: up to 15 kV, sample size is up to 25 mm in diameter and 30 mm height. Magnification range is from 20X to about 30,000X and a resolution as low as 10 nm for conductive samples.

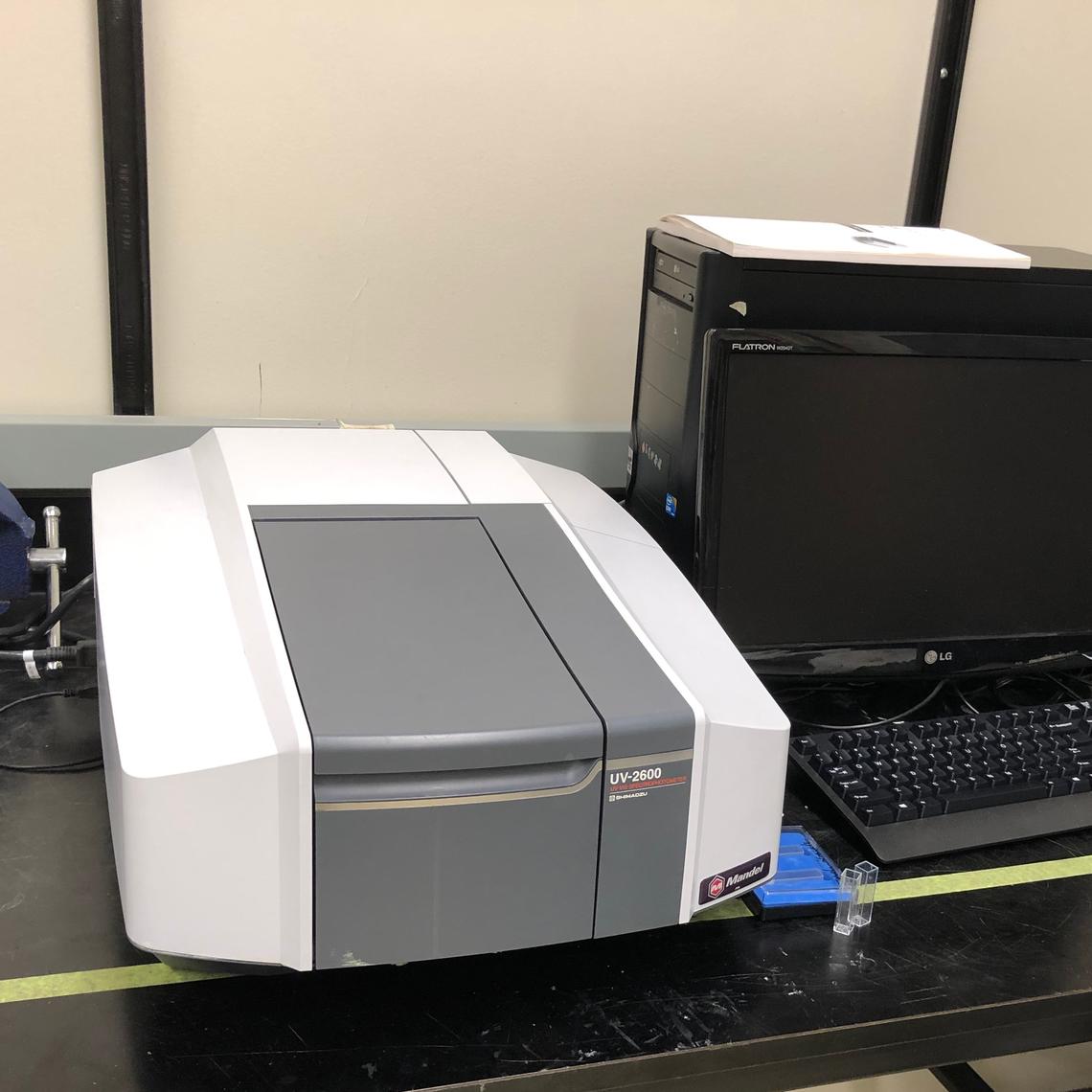

This technique allows for quantitative determination of analyte concentration in solution (using Beer’s law), in addition to the compound’s spectrum over the UV-Vis wavelength range. It measures and compares the light intensity before and after passing through the sample. Spectroscopy is suitable for samples that can be completely dissolved, and the analyte must absorb light in the UV or visible range. It is not suitable for fluorescent analytes or opaque or colloidal systems. One can measure the concentration of unknown samples via measuring and comparing a series of standards of known concentration using standards that bracket the unknown sample concentration; in other words, identification is done by comparing the absorption spectrum with the spectra of known compound. Here are few examples of where UV spectroscopy is used:

- Study rate of reaction

- Determine rare equations of reaction

- Environmental process

- Quantitative and qualitative analysis

- Detection of impurities

- Detection of functional group

Model: Shimadzu UV 2600

Wavelength bandwidth: 185-1000 nm; sample requirement: 2 mL; single monochromator; spectrum and photometric module (concentration).

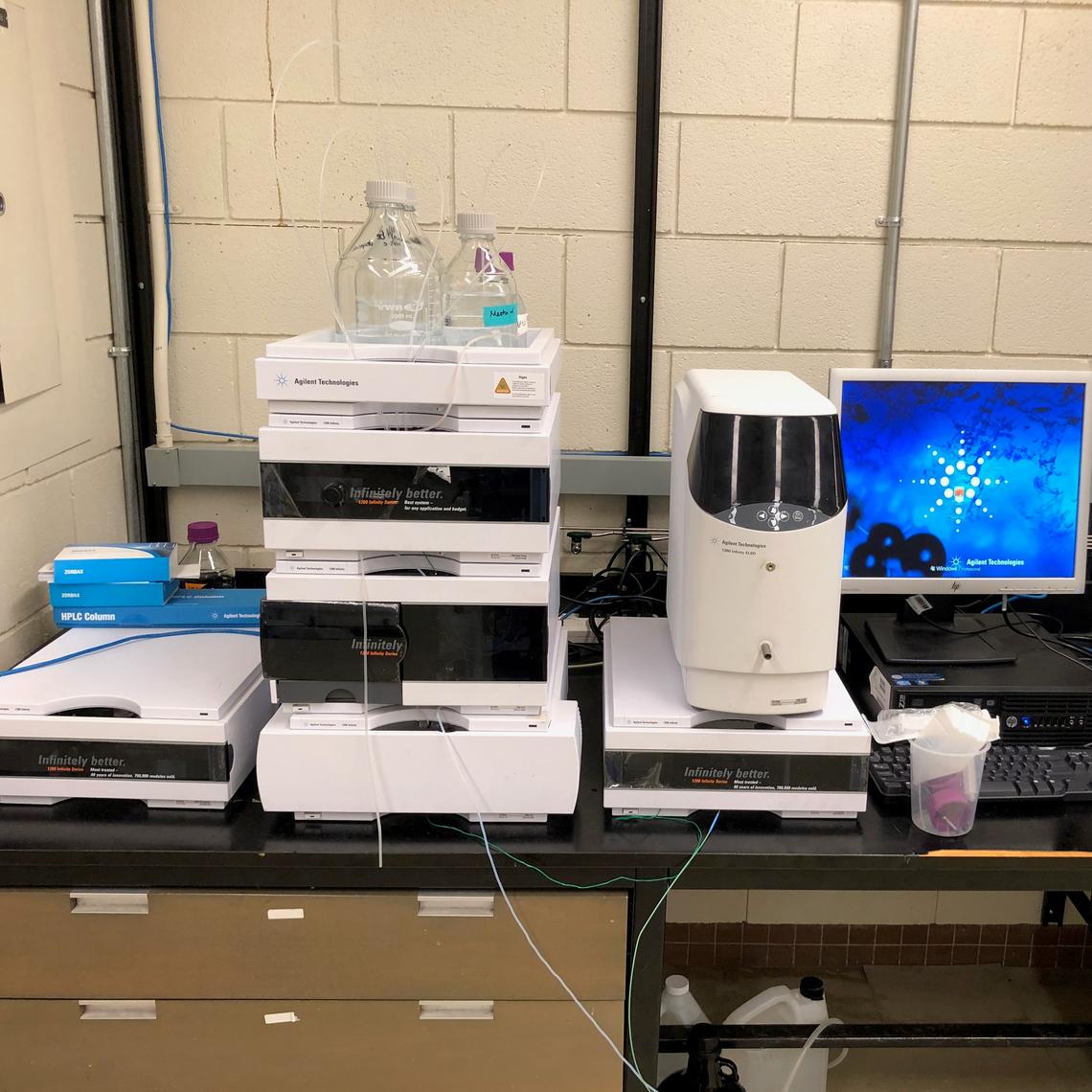

Uses chromatography to separate and quantify components present in a liquid sample. The system has diode array (DAD), refractive index (RID) and Fluorescence (FD) detectors.

Model: Agilent 1260 system

Technique using centrifugal force application to separate particles or droplets from a suspension system. The behavior of suspended particles and droplets in the centrifuge depends on their size, shape, density, viscosity of the medium and rotor speed, and they can be separated in a various ways.

Model: Beckman Coulter J265-XP

Speed range: 100-26000 rpm, time interval: up to 180 min; Temperature: -10 to 40 0C; Acceleration/Deceleration: Max or slow. Three rotors are available:

- JA-30.50: max. RPM: 26,000; max. capacity: 8x50 mL

- JLA-16.250: max. RPM: 16,000, max. capacity: 6x250 mL

- JLA-9.1000: max. RPM: 9,000, max. capacity: 6x1000 mL

TOC uses a simple principle of oxidation via combustion, and sample pretreatment is not necessary. Samples are heated to 680ºC in an oxygen rich environment inside combustion tubes, generating CO2 that is detected using an infrared gas analyzer (NDIR). From the amount of the CO2 generated, the “Total Carbon” (TC) content of the sample can be determined. Standard solutions are used to predetermine calibration curve in order to measure the TC concertation of an unknown sample. To determine the inorganic carbon (IC) content in the sample, it is acidified and sparged with a carrier gas, so that the IC is converted to carbon dioxide, stripped and detected by the NDIR detector. To measure the TOC in the sample, both IC (inorganic carbon) and TC (total carbon) of the sample are measured and the IC is subtracted from TC to determine the TOC. Applications of TOC include but are not limited to:

- Environmental analysis (waste water treatment, surface and ground water, drinking water)

- Pharmaceutical industry (compression of various oxidation techniques)

- Chemical industry (e.g. TOC contamination in industrial samples)

Model: Shimadzu TOC-VE

Measurement range: 0-3500 mg/L; sample injection volume: 50 ug; manual injection; measured parameters: TC, IC, TOC; liquid sample analysis.